Cao Yajun (left), a "great country craftsman" in the national architectural decoration industry, works in the start-up area of Shenzhen Guangming Science City. Xinhua news agency

Xiong Guoan, the inheritor of Jingdezhen traditional thin-shell porcelain making skills, is "benefiting the blank". Xinhua news agency

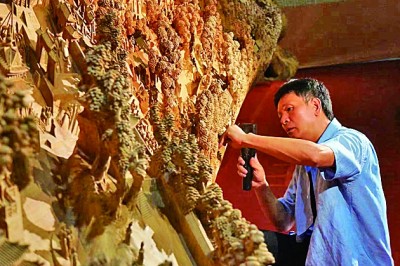

Zheng Chunhui, a senior arts and crafts artist, is creating. Bright picture

In Xi ‘an, Shaanxi Province, Hu Min, a "national technical expert", is carrying out flame cutting. Xinhua news agency

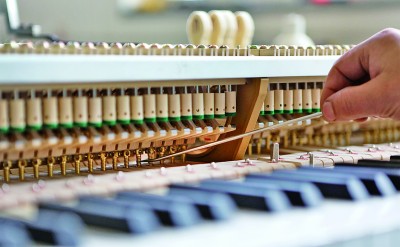

Liu Yulei, a senior assembler of grand piano in Yingkou, Liaoning, assembled piano parts in the workshop. Xinhua news agency

Wang Shangdian, a senior lathe technician and lathe skill expert in Jinxi Petrochemical Company of China Petroleum, is using calipers to measure parts data. Xinhua news agency

editorial comment/note

Skilled workers are an important force supporting China’s manufacturing and China’s creation. Recently, the General Secretary of the Supreme Leader sent a letter to congratulate the holding of the first great country craftsman innovation exchange conference, stressing: "The working class and the broad masses of working people in China should vigorously carry forward the spirit of model workers, labor and craftsmen, adapt to the needs of the scientific and technological revolution and industrial transformation in the world today, study hard, study deeply, be brave in innovation and be the first, constantly improve their technical skills, and contribute wisdom and strength to promoting high-quality development, implementing the strategy of manufacturing a powerful country, and building a socialist modern country in an all-round way." As an outstanding representative of skilled talents, artisans in big countries are superb in skills and hard-working. They build their dreams with dexterous hands and devote themselves to their country with dedication. How did they feel and touch when they received the congratulatory letter from the general secretary? How to play a better role and contribute wisdom and strength to promoting high-quality development, implementing the strategy of building a strong country and building a socialist modern country in an all-round way? In this issue, five craftsmen from big countries are invited to tell their stories of struggle, and experts are invited to make suggestions and analyze them.

[First-line narration]

Sow the seeds of "ingenuity" and strive for Excellence

Narrator: Chen Zhaohai, the chief skill expert of China Communications No.1 Navigation Bureau No.3 Company.

A few days ago, we were attending the first great country craftsman innovation exchange conference online, and when we heard the news that the general secretary sent a congratulatory letter, we suddenly "boiled" with joy and felt glorious and proud.

I have been engaged in surveying for 27 years, and I have been on the front line of building ports, dams, roads and bridges. Years of work have made me deeply feel that measurement is like the "eye" of the project. Only by measuring more accurate data can the project of a big country be completed accurately. For example, the observation accuracy of calipers can only reach centimeters, and millimeters need to be estimated by ourselves. How to read the millimeter estimate more accurately? I have practiced this basic skill for 10 years.

At that time, because the measuring instrument total station was more expensive, the newly graduated "raw melon and an egg shaped thing" rarely had a chance to get started, so I helped master Zhao Zhenguo and carefully recorded every operation step. One day, the site builder was anxious for a set of measurement data, and it happened that the master was on vacation. At the urging of everyone, I shouldered the total station and rushed to the scene. It was my first independent measurement. Because I was nervous, I repeated the measurement and calculation several times before reporting the data. After the master came back, he not only didn’t blame me, but also praised me again and again. This encouragement and trust made the seeds of "ingenuity" take root in my heart.

In 2013, I participated in the construction of Dalian Xinghai Bay Bridge. In the construction of the main bridge, in order to ensure the balanced stress of the "two towers and three spans" of the bridge, the accuracy of suspension cable installation is extremely high. Every time we organize survey and lofting, we need to climb to the top of the 120-meter-high cable tower for operation. Because the construction area is more than 1 km offshore, even if it is calm, the towering cable tower will keep swinging. During more than 300 days and nights of bridge construction, I will take the lead to climb to the top of the tower as long as my work requires, and lay points and lines at an altitude of 100 meters, which ensures that all suspension cable installations are completed at one time, and also accumulates experience for similar projects in China.

Dalian Bay subsea tunnel project is the first immersed tunnel built in the cold sea area in China, and there is no experience for reference. The accuracy of our survey work should be based on the Zhuhai-Macao Bridge in Biaogang, and the out-of-tolerance accuracy should be within 5 cm. To this end, I and the technical center of the third company of No.1 Navigation Bureau have devoted themselves to tackling the problem of "multi-beam sounding system scanning replacing the traditional acceptance method of hydraulic concealed works". In the construction of subsea tunnel, it is normal that the wind and waves bump. However, multi-beam equipment needs to measure strictly according to the horizontal and stable geometric relationship, and the wind and waves greatly affect the accuracy of data. Inspired by the folding umbrella, we proposed to customize the connecting frames for the five sub-instruments of the multi-beam system. After four months of exploration, we finally developed a detachable connector that can be spliced and suitable for any ship type, which made the instrument grow "hands and feet" to grasp the ship’s side and stand firmly on the seabed. Compared with the workload of single-beam equipment of 6 hours, multi-beam equipment only needs 30 minutes, and the out-of-tolerance accuracy reaches the standard of 5 cm.

Now, I have also become the master of my disciples, and that "ingenuity" seed has been spread to more people’s hearts. I will set an example and teach my disciples to do, love and specialize in one line, so that more young people who are interested in this will embark on the road of becoming talented and serving the country with skills.

Skilled workers have both skillful hands and "ingenious thinking"

Narrator: Liu Li, an oil production worker of Team 48, No.6 Operation Area, No.2 Oil Production Plant of Daqing Oilfield Co., Ltd.

I was born and raised in the oil field, and I am a veritable "second generation of oil". After his father retired, he transferred to work in Daqing Oilfield. He once participated in the battle of Daqing Oilfield with Wang Jinxi. "Consolidate your achievements and continue to work hard" is what my father taught me from an early age. In 1993, I entered the "old benchmark" oil production team with excellent style — — Team 48 works.

At that time, everyone was working hard, and this spirit of striving for the top deeply infected me. In order to master technology better, I always carry a technical book in my bag. I go to the well during the day and try to figure it out against the real thing, and I go home to sort out my notes at night.

Adding packing and changing belts is our daily work. A belt weighing more than 30 kilograms, I always riveted enough to drag it to the operating table. Although I have worn calluses on my hands, I have become more and more skilled in changing belts, creating a record of changing belts for 15 seconds, which has attracted the admiration of the masters.

The crowbar, pipe wrench, wrench and screwdriver are my four-piece sets when washing wells, which add up to 15 kilograms. In order to reduce the weight, I changed "four pieces into one piece", and the total weight was reduced to 2.5 kg, which improved the working efficiency.

After tasting the "sweetness" of innovation, I wondered how to make the sealing ring in the packing box "pop out" automatically. At that time, the sealing ring in the packing box could only be replaced by pinching, which took at least 40 minutes at a time, and the oil production machine had to stop working. Once, I held a tube of lipstick in my hand and slowly turned the bottom of it, and the paste inside gradually exposed, which made me find inspiration at once. So, by disassembling the internal structure of lipstick, I developed the "up-down adjustable packing box", which shortened the operation time by three quarters and prolonged the service life of the filler by six times. Our skilled workers have not only "brute force" but also "ingenuity".

After 2003, I have a number of identities such as trainer, coach and senior technician, and I have an additional responsibility of training students. In 2011, Liu Li Studio was established. From the initial team of two people, it gradually developed into an innovation and efficiency alliance covering 35 types of work such as oil production and gathering and transportation, with 537 members. Just in March of this year, I was awarded the title of "Artisan of the Great Country of the Year". I have always felt that "luck" is not the only way to become a talent and serve the country with skills. Only with correct thinking, firm will and down-to-earth attitude can we achieve something.

A few days ago, the General Secretary of the Supreme Leader sent a letter to congratulate the first great country craftsman innovation exchange conference. As soon as the news came out, my friends and I were encouraged and competed to forward it. In the future, I will continue to work hard, do a good job of mentoring and continue to pursue my dreams with a new generation of oil people.

Push hard with your heart and let the sound cross the mountains and seas.

Narrator: Zhang Luming, radio communication designer of Guangzhou Haige Communication Group Co., Ltd.

I have been interested in wireless communication technology since I was a child, and I like playing with the radio. In 1984, at the age of 21, I graduated and came to the predecessor of Guangzhou Haige Communication — — Work in the state-owned 750 factory.

At that time, the spring breeze of reform blew the land of South Guangdong, and it became the focus of the research team to catch up with the international advanced level. In the process of single board debugging, the frequency index has been unable to meet the requirements of the whole machine. In order to solve this "stuck neck" problem, I led the team to explore and attack day and night. One day, a group of birds chirped away from the telephone pole outside the laboratory window. I looked up at them and happened to find a ceramic insulating connector between the wire and the telephone pole. So I changed my mind, not limited to improving the printed board material itself, but adding high-performance insulating materials between the printed board and key devices. In the end, the problem that plagued the team for several months was solved. This also makes me feel that innovation needs accumulation and persistence.

For more than 40 years, I have been fortunate to participate in and witness the development of four generations of communication technology in China. My goal is always to send and receive radio waves carrying sound with high fidelity, so that sound can cross mountains and seas.

In the 1990s, my company was on the verge of bankruptcy. The temptation of high salary once made me want to leave. However, I finally chose to stick to it. In 2000, Hagrid Communications was established. Flexible mechanism construction makes the relationship between enterprises and employees closer. In 2006, Luming Laboratory named after me was established. Today, "Luming Lab" has trained more than 100 technical backbones for Hagrid Communication, and they have successively broken through dozens of key technologies in the communication field, and many technologies have reached the world’s leading level.

In March of this year, I was elected as "Artisan of the Great Country of the Year" in 2021. What is even more surprising is that on the eve of "May 1st" International Labor Day, General Secretary of the Supreme Leader sent a congratulatory letter to the first great country craftsman innovation exchange conference. I will keep in mind the entrustment of the General Secretary, seize every minute to solve the difficult problems in the field of wireless communication technology, and "make a living and be good at it" to make China famous in the world.

"Local Experts" Running on the Road of Innovation

Narrator: Tan Wenbo, a tool worker and senior technician of China Petroleum Group Western Drilling Engineering Co., Ltd.

Before I went to work in the oil field, most of my impressions of Xinjiang came from the description in the textbook. My father was also an oil worker. In the era when he worked, the conditions were even more bitter. The older generation of oil people stood up the industrial backbone of the Republic with the spirit of fighting in the world.

When I first started working, I was thin and small, and I felt very tired in the face of high-intensity labor requirements, so I tried to make some small tools such as levers and zip lines to save my effort. These small productions have effectively improved the work efficiency and planted the seeds of invention and creation for me.

What really ignited the innovative flame in my heart was an experience of repairing imported equipment. At first, we asked foreign experts to repair it, but when the other party checked it a little, it said that it could not be repaired, and suggested that we replace the whole machine. However, giving up maintenance will have a huge impact on production. I volunteered, holding my breath in my heart: What foreign experts can’t fix, we China mechanics can fix it. So, I asked college students who know foreign languages to consult materials, disassemble machines and reassemble them … … After some repairs, the machine returned to normal. Later, I repaired a number of foreign imported equipment, and my colleagues called me a "soil expert".

Since then, the idea of "fighting for breath" has driven me to keep advancing on the road of invention and creation. For example, the original cable bridge plug setting tools are imported from abroad, so there are great risks in storage, transportation and use, and the equipment I designed is driven by electro-hydraulic pressure, which can effectively improve production efficiency and safety.

Along the way, I have won many honors such as "National Model Worker", "The Most Beautiful Worker in China" and "Great Country Craftsman 2018 Person of the Year". But I always feel that I still have a lot to do on the road of technological innovation. It is the older generation of oil people who constantly give us strength. I want to pass on this spirit one by one and lead more skilled people to run faster on the road of innovation.

Carve green water and green mountains to record the beautiful times.

Narrator: Zheng Chunhui, senior arts and crafts artist of Fujian Tenghui Craft Co., Ltd.

I was born in the countryside and have been interested in artistic creation since I was a child. There is no money to buy paper and pens at home, so I draw on the ground. Later, by coincidence, I began to learn wood carving skills and gradually became a wood carving craftsman.

In the past, our local woodcarving was mainly about characters, and the landscape was just a foil. But the beautiful mountains and rivers in my hometown always haunt me, and my childhood memories and classical poems I have read always urge me to carve them. So, I began to try to use the composition of landscape painting to create woodcarving with cultural elements such as China’s classical poems.

I have been thinking about how to integrate traditional skills into modern society. In my eyes, the creation of landscape woodcarving should not only make traditional landscape painting stand up and live, but also reflect the reality and record the times. Later, I spent several years on a camphor tree with a length of more than 12 meters, a height of more than 3 meters and a width of more than 2 meters, and created a picture of the Riverside Scene at Qingming Festival with special significance by innovating the techniques of hollow carving, through carving and Putian subtle through carving. Because of the huge volume of the work, it also won a Guinness World Record.

Unexpectedly, a woodcarving work has become a window to show our traditional skills, history and culture, and also a link to communicate with the world culture.

In 2020, I was awarded the "Artisan of the Great Country of the Year", and the nine people who won the prize with me were all technical masters from engineering and technical positions. I think this award is actually awarded to the group of folk craftsmen I represent, which represents the praise and affirmation, encouragement and spur of the party and the state to all folk craftsmen.

I think our fingertips not only inherit traditional skills, but also a craftsman spirit that dares to innovate and be the first. Facing the future, I will certainly live up to the earnest entrustment of the Supreme Leader General Secretary, lead more young people who are interested in it, and use our hands to lift more "Made in China" handicrafts to go abroad and amaze the world.

关于作者