Phoenix Network Technology News Beijing time on September 24 th news,Elon Musk is currently running a number of ambitious technology companies by himself.While serving as CEO of Tesla and SpaceX, Neuralink, a brain-computer interface company, and Boring Co, a tunnel excavation company, were also established. Moreover, he is still busy with the lawsuit with Twitter.

Due to the lack of skills, Musk needs to rely on a large team of senior deputies to perform specific affairs. In Tesla, there are now more than 20 people responsible for maintaining Tesla’s business operations.

His direct subordinates often change with the change of the company’s strategy or organizational structure, and occasionally they are "fired on the spot" by the capricious CEO, or voluntarily resign.

Musk

27 senior deputies

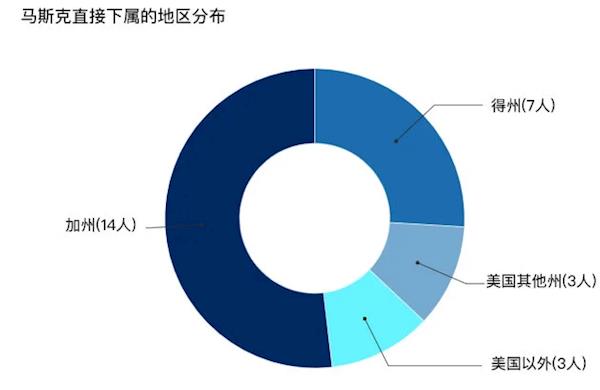

According to the data summarized by foreign media, as of September 2022, Musk had 27 direct subordinates in Tesla. These data come from interviews with Tesla’s current and recent employees, LinkedIn profile, Tesla’s internal and public records, and may not include all those who report to him.

Musk’s direct subordinates are mainly concentrated in the United States, and more than 90% are men.Although he has moved Tesla’s headquarters from California to Texas, about half of his direct subordinates (14 people) remain in California. There are only 7 people in Texas, accounting for 22%.

These include Zachary Kirkhorn, CFO of Tesla, Allie Arebalo, Director of Human Resources, Luo Shang Thomas, Vice President of Global Supply Chain Management, Omead Afshar, Head of Texas Factory, David Lau, Vice President of Automotive Software, and Pete Bannon, Vice President of Hardware Design Engineering.

The task is arduous

As Tesla strives to put the new factories in Austin, Texas and Glenhead, Germany into full production and make progress on many other goals, Musk will need to rely on these senior deputies.

Musk has told shareholders and fans that Tesla will "solve the problem of fully autonomous driving (FSD)" this year., improve car service and maintenance, and start delivering Cybertruck pickup trucks in mid-2023.

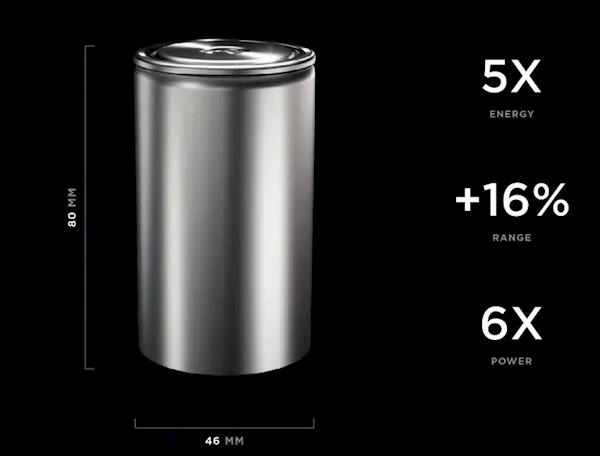

He also said that Tesla will strengthen its battery manufacturing capacity, with the goal of producing its own 4680 battery with a capacity of 100 GWh this year, which is enough to power more than 1 million Tesla cars.

Tesla 4680 battery

Moreover, Musk’s direct subordinates also need to lay off employees in the uncertain economic situation recently. Musk suddenly announced a large number of layoffs at the end of May this year, when Tesla faced a challenging second quarter, just as the Russian-Ukrainian war broke out and the epidemic continued.

In June this year, Tesla closed the entire Autopilot office in san mateo, California, and fired at least some employees..

These employees were previously approved to work remotely, but did not agree with Musk’s order to work at least 40 hours a week in Tesla’s office.In June this year, Musk mentioned in an email to Tesla employees that he "felt very bad" about the economy.

China executives

Three of Musk’s direct subordinates work outside the United States, and one of them is Zhu Xiaotong, global vice president of Tesla and president of Greater China.

Zhu Xiaotong joined Tesla in April 2014 as the project director of Tesla China Super Charging Station. In December of the same year, he took over as Tesla’s global vice president and president of China. In 2018, he was responsible for the construction and operation of Tesla’s Shanghai factory, and in 2019, he was promoted to president of Greater China.

Zhu Xiaotong and Musk

One of Tesla’s main businesses in China is the Shanghai Superfactory, which not only meets the demand of China market, but also becomes an export hub.

According to the data released by the China Ride Association, in August this year, Tesla sold 76,965 vehicles in wholesale, 42,463 in export and 34,502 in domestic retail. From January to August this year, Tesla has delivered 399,939 vehicles, which is only over 80,000 vehicles short of the 484,130 vehicles delivered in 2021, including nearly 160,000 vehicles exported and over 240,000 vehicles delivered domestically.

During the epidemic, the production of Tesla’s Shanghai factory faced severe challenges. According to people familiar with the matter, Zhu Xiaotong has been living in the Shanghai Superfactory since March 28th, and is responsible for supervising and ensuring the operation of the factory.

Musk has repeatedly praised the Shanghai factory and thought that the Shanghai super factory is difficult to be surpassed."I must admit that our Shanghai team is really excellent." He said.

Musk is a workaholic, likes to work overtime, and once slept in the factory.Therefore, he praised the diligence of China people. "There are many very talented and hardworking people in China who firmly believe in manufacturing. They not only stay up late, but also work diligently at three in the morning, and even don’t leave the factory at all. Americans try not to go to work. " Musk said this in May this year.

Tesla Shanghai factory

Recently, Tesla’s Shanghai factory has completed the expansion work. Tesla Giga Shanghai (Phase I) Phase II production line optimization project was completed on September 1st and started debugging. The expected acceptance period is from September 1st to November 30th.

The total investment of the project is as high as 1.2 billion yuan, which is an expansion in Tesla’s existing factory, mainly by increasing the production tempo to expand the production capacity. The EIA report released in November last year showed that the production line optimization projects were mainly the expansion of stamping workshop, body workshop, painting workshop, assembly workshop and logistics operation center.

There are quite a few resignations.

Although Andrej Capassi, senior director of artificial intelligence at Tesla, was not among those laid off or fired by Musk, he officially announced his resignation from Tesla in July. Ashok Elluswamy, the head of Autopilot, reports directly to Musk for the time being.

According to internal documents, other direct subordinates of Musk who left Tesla in 2022 include Chris Lister, former vice president of Nevada Super Factory, and Jean Frazier, senior director of employee relations at Tesla.

David Searle, the former head of Tesla’s legal department, still works in the company, but insiders said that they expect Searle to leave in the next few months because he previously managed more than a dozen employees, but now there is only one direct subordinate on the internal organization chart.

According to public and internal records, Dinna Eskin, senior legal director of Tesla, is now the manager of the company’s legal department, and is actually the company’s general counsel. Since the end of 2019, Tesla has not officially hired a person with the title of general counsel. (Author/Xiao Yu)